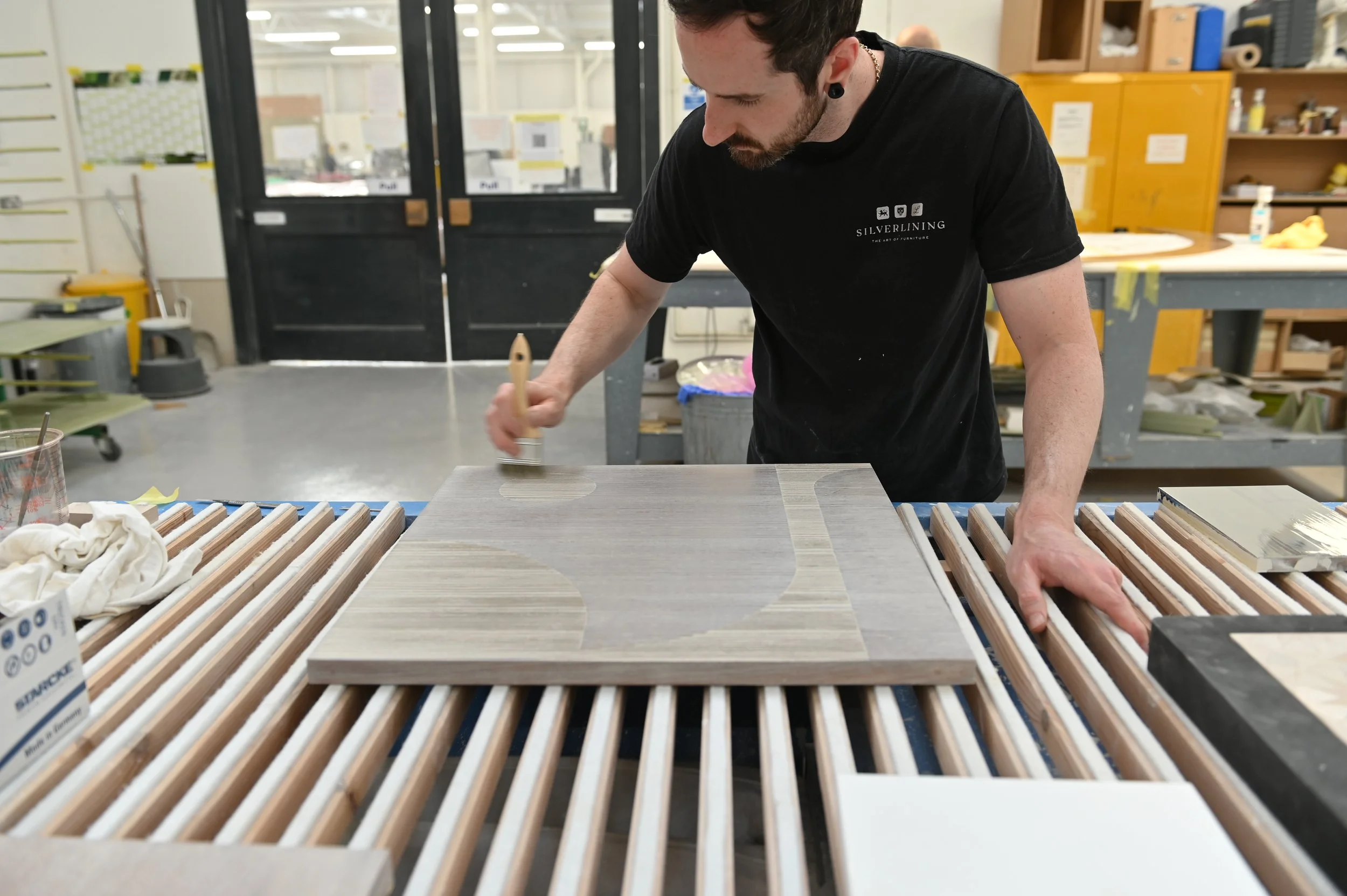

Making Layers in Time: Inside The Workshop

Creating Studio SL's first limited edition collection meant transforming vision into reality through hundreds of hours in our North Wales workshop. Here's how eight pieces came to life.

Wave Console: Capturing motion

The Wave Console began with a sketch capturing the movement of a breaking wave. Leather was the only material that made sense, its natural ability to curve and drape made it perfect for expressing this motion. But how do you make something soft hold such a complex shape?

Bio-based flax composite became the hidden architecture, creating strength from within. Then came the meditation: over 1,200 strips of vegetable-tanned coach-hide leather, placed one by one. These cordings - salvaged from waste - in Havana, Papaya, and Mocha tones, each spokeshaved smooth as it followed the wave's curves. We left the fibrous cut edge exposed, turning traditional leatherwork on its head.

Lumen Side Table: playing with light

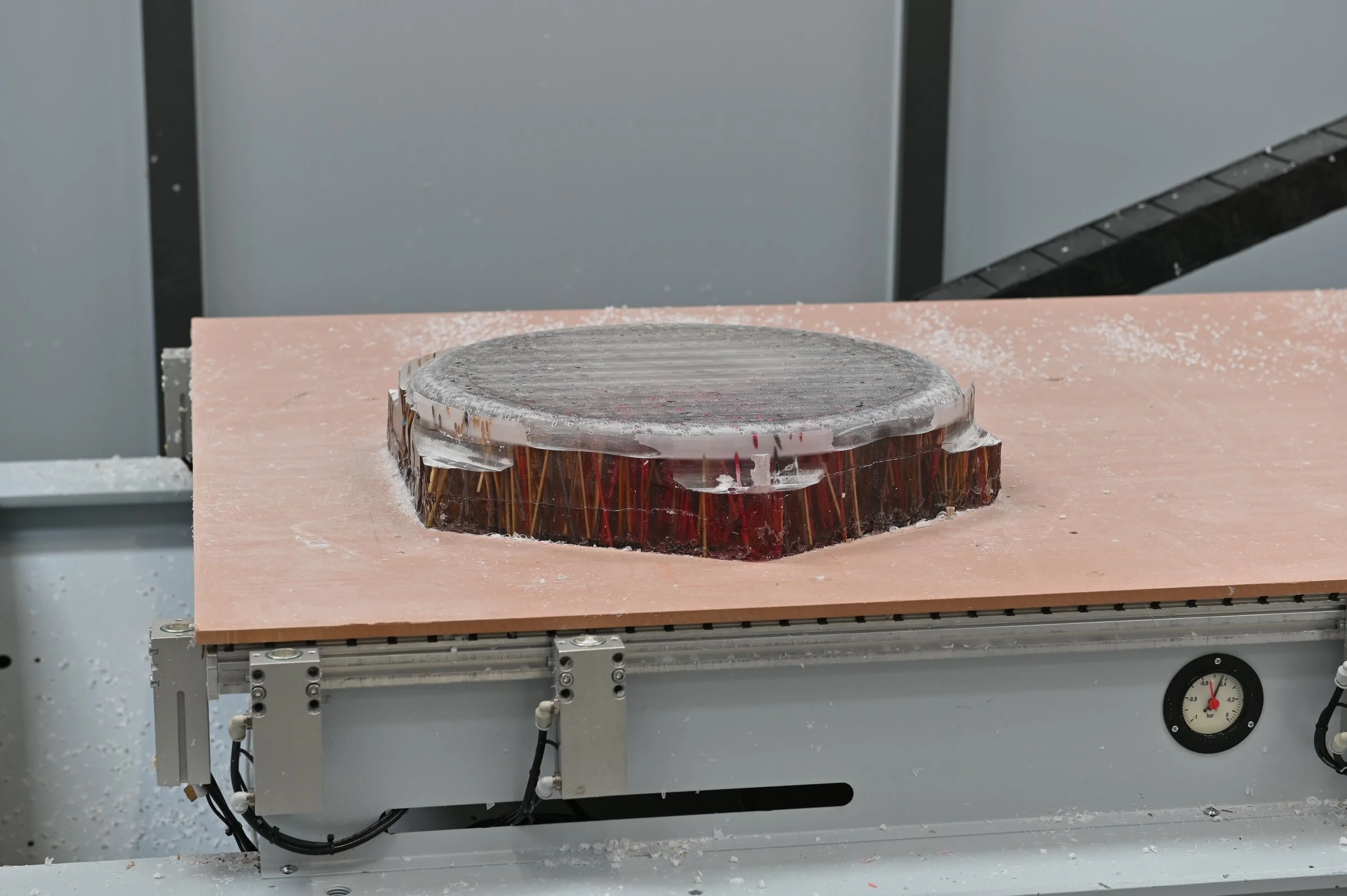

Our materials specialist has spent years understanding straw marquetry, learning how it catches and holds light. For Lumen, the idea was to use straw standing on end rather than laying flat, revealing its translucency.

Eight autumnal hues of French wheat straw were hand-laid end grain into the mold, radiating from a central clear window. Casting them in crystal-clear resin allowed light to pass through completely, reflecting warm colours and casting shifting shadows below.

Three oversized English oak legs anchor the table, each hand-turned and chip-carved with patient hands. Natural oil finish brought out the grain.

Slice Desk: where history meets precision

The Slice Desk celebrates restraint. Its cantilevered form demanded complex hand-cut box joints fitted with absolute precision.

The deep blue finish tells its own story. Oak gall ink: the very same ink used to write the Magna Carta, enriched the wood with colour that feels both ancient and contemporary. A final touch of liming wax with crushed mica added subtle shimmer.

When there's no ornamentation to hide behind, every angle must be exact.

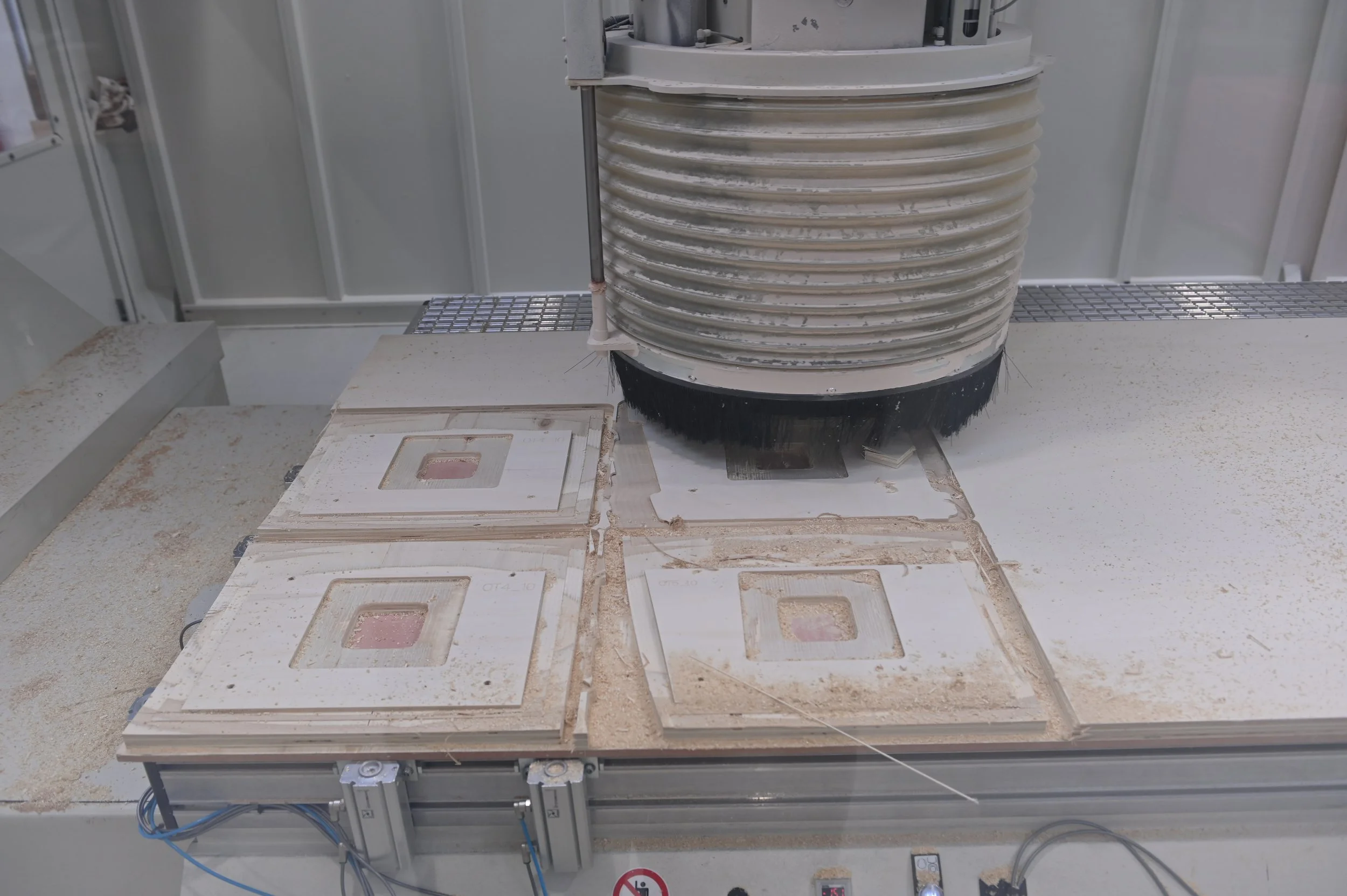

the leather mirrors: two conversations

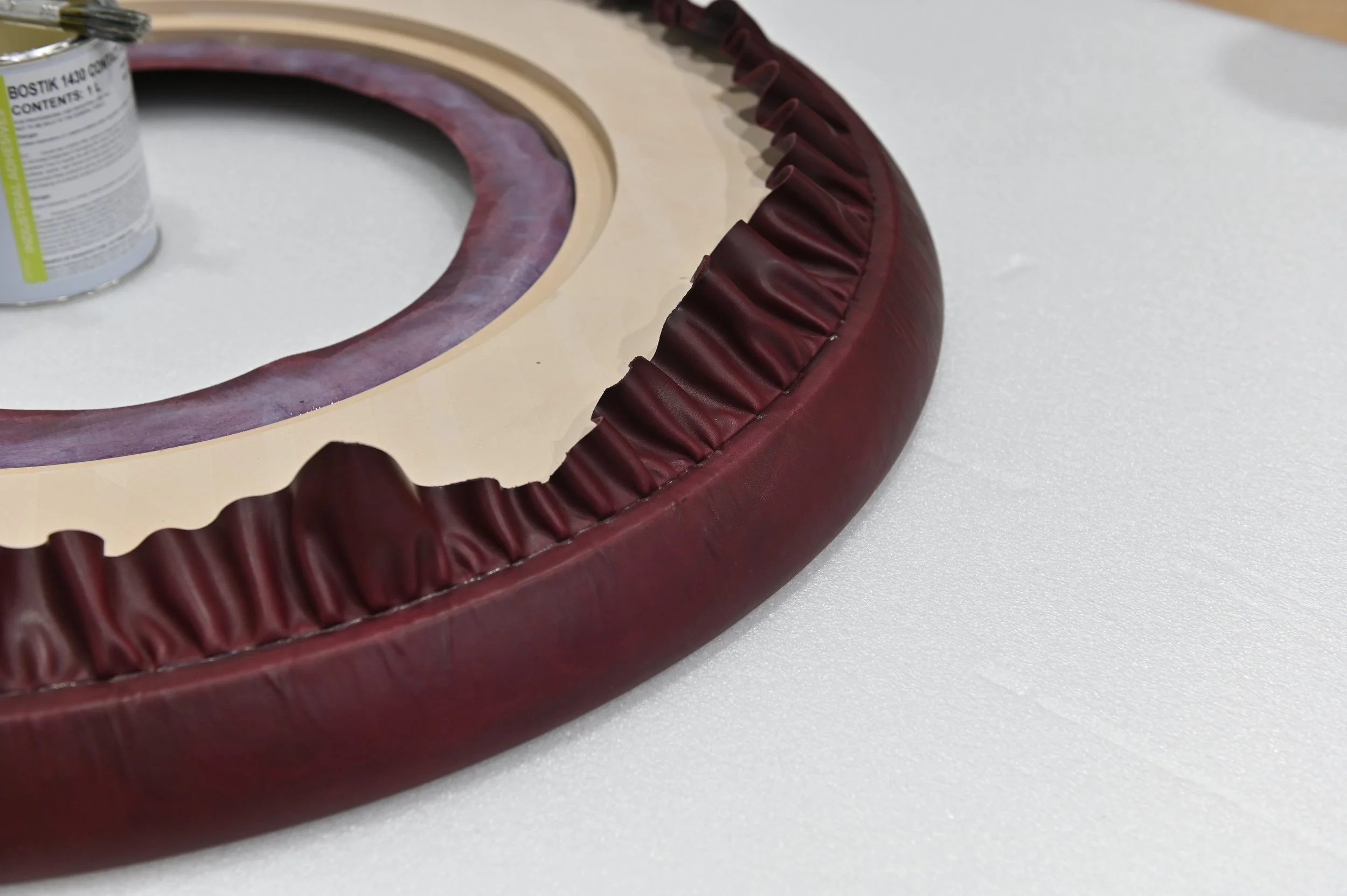

The Ripple Mirror came to life through force and patience. Two burgundy leather hides were soaked, then pressed under immense hydraulic pressure into CNC-machined molds, forming concentric waves like a raindrop's impact on still water. After days of drying, small stamps were pressed into the surface to create the play of light and shadow that makes water feel alive.

The Chroma Mirror took a gentler path. Two hides were moulded into soft curves, then became a canvas. Water-based dyes were applied with calligraphy brushes, layer after layer, enhancing the leather's natural grain. Two circular mirrors one silvered, one golden, were set into gold-plated brass surrounds.

Cracked Earth: nature’s patterns

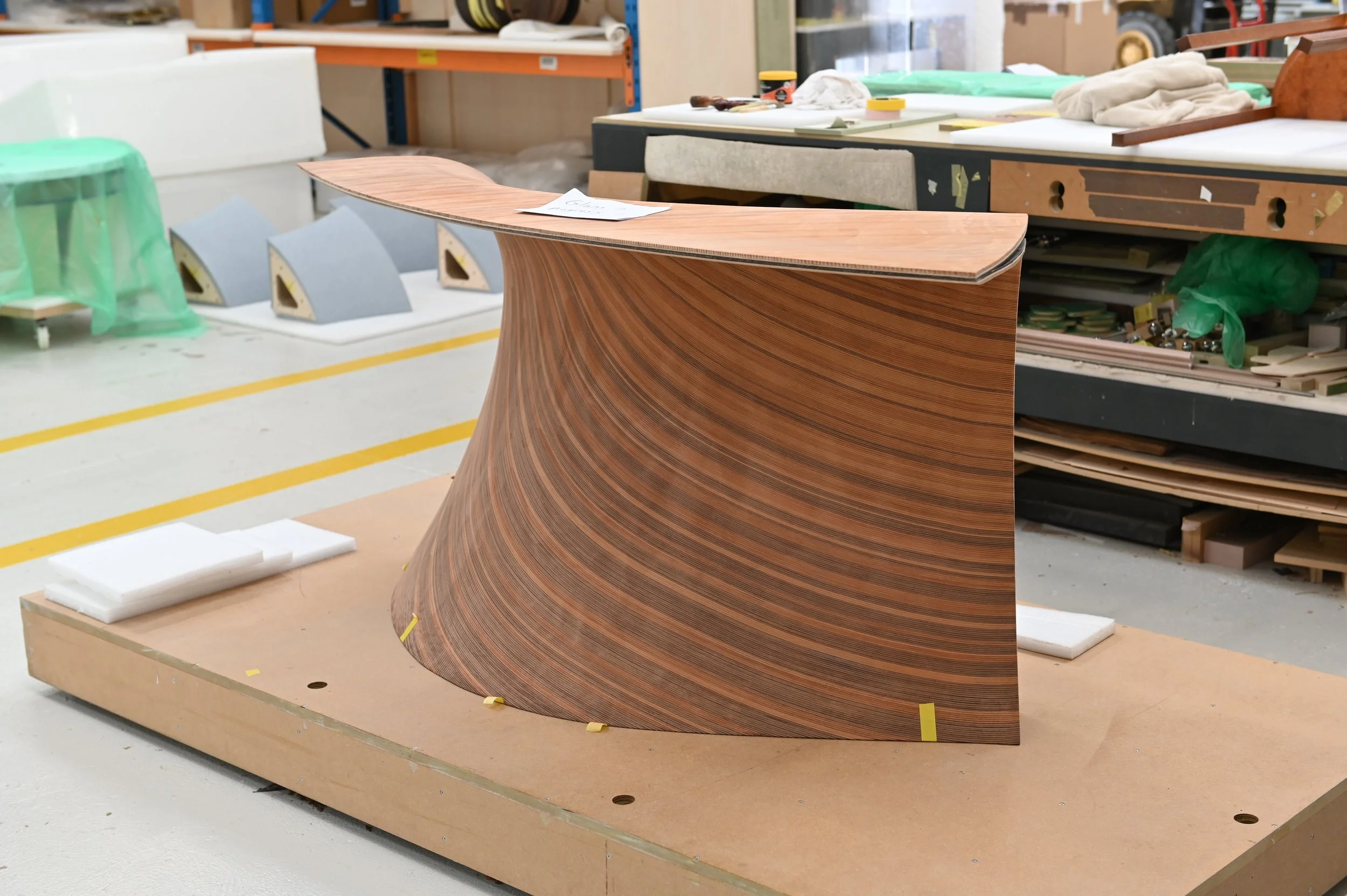

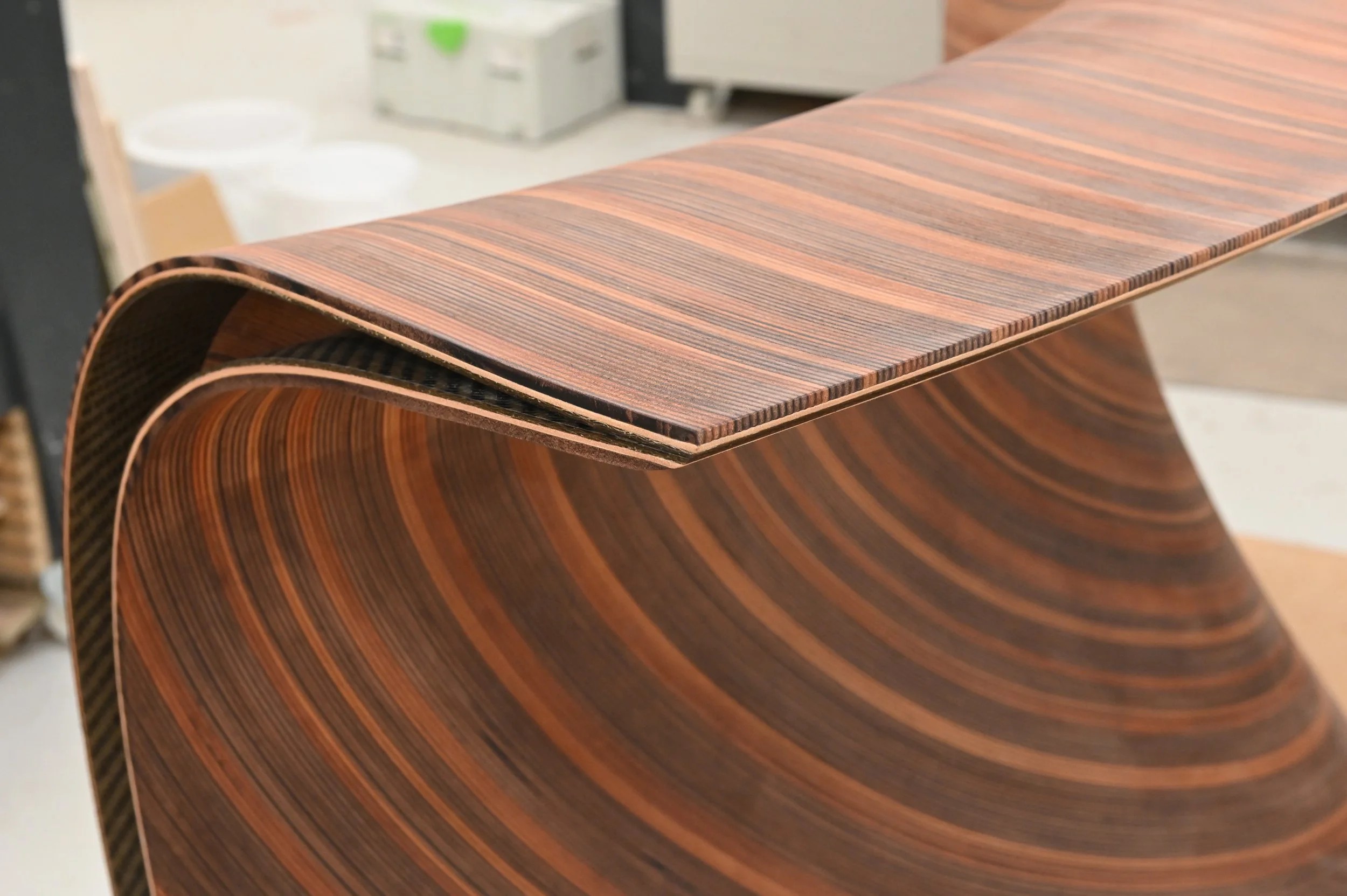

English end-grain oak oysters, cross-sections revealing a tree's life in rings were cut, darkened with walnut ink, then highlighted with pale liming paste. The shaped edges, built from laminated oak veneer, were hand-sculpted to echo the soft contours of dried earth.

Polished bronze inlays sit between the oak like precious metal filling ancient cracks, each piece cast, machined, and hand-polished to mirror shine.

Puzzle Panels: finding rhythm

Locally sourced Larch was sandblasted to leave denser winter grain standing in relief—a surface that plays with light and shadow. Walnut ink and off-white liming paste created tonal contrast. The panels work together in mirrored pairs, matched sequences, or organic layouts, each configuration creating its own rhythm.

It is then for the client to decide whether they cover one wall, an entire room, or play with the panels from floor to ceiling, a truly versatile piece.

Hundreds of hours. Techniques reaching back millennia sitting beside parametric design. Hands and machines in conversation. Forty years of knowledge made physical.

This is how Layers in Time was made.

Subscribe to our newsletter

Sign-up to receive our newsletter and discover our stories, collections and latest innovations.