The Ancient Art of Leather Cording

Leather cording (the technique of wrapping narrow strips of leather around handles, grips, and structural element) has existed for as long as humans have worked with hide. What began as pure function has evolved into decorative craft, one that Silverlining has reimagined for contemporary furniture.

A Grip on History

Leather cording began in necessity. Vikings wrapped it around axe handles so their grip wouldn't slip in battle. Japanese sword makers developed tsukamaki, the art of wrapping leather around katana grips in precise diamond patterns. Ship riggers bound it around ropes and rails so sailors' hands would not blister. Gunsmiths wrapped shotgun grips because the finest weapon means nothing if it slips from your hand.

What started as survival became craft. The wrapping itself, its tension, rhythm, and finish, evolved into a mark of quality. A well-corded grip showed that someone cared about details others might overlook.

The Technique

Watch someone cord leather and you are watching a conversation between hand and material. The leather is cut into strips, each millimetres wide, each exactly the same thickness. Precision matters. One strip too thick and the pattern fails. One too thin and it snaps under tension.

The leather is dampened to make it pliable, then the wrapping begins: spiralling, overlapping, interlocking. The maker's hands adjust tension by feel alone. As the leather dries, it contracts, tightening around whatever lies beneath.

Some craftsmen burnish the surface until it glows. Others leave the cut edge raw, the fibrous texture speaking of material shaped by hand rather than polished to perfection. What emerges is unmistakably handmade: tiny shifts in tension, the trace of hands adjusting mid-wrap.

Ancient Meets Contemporary

At Silverlining, we have taken this centuries-old technique and asked it new questions.

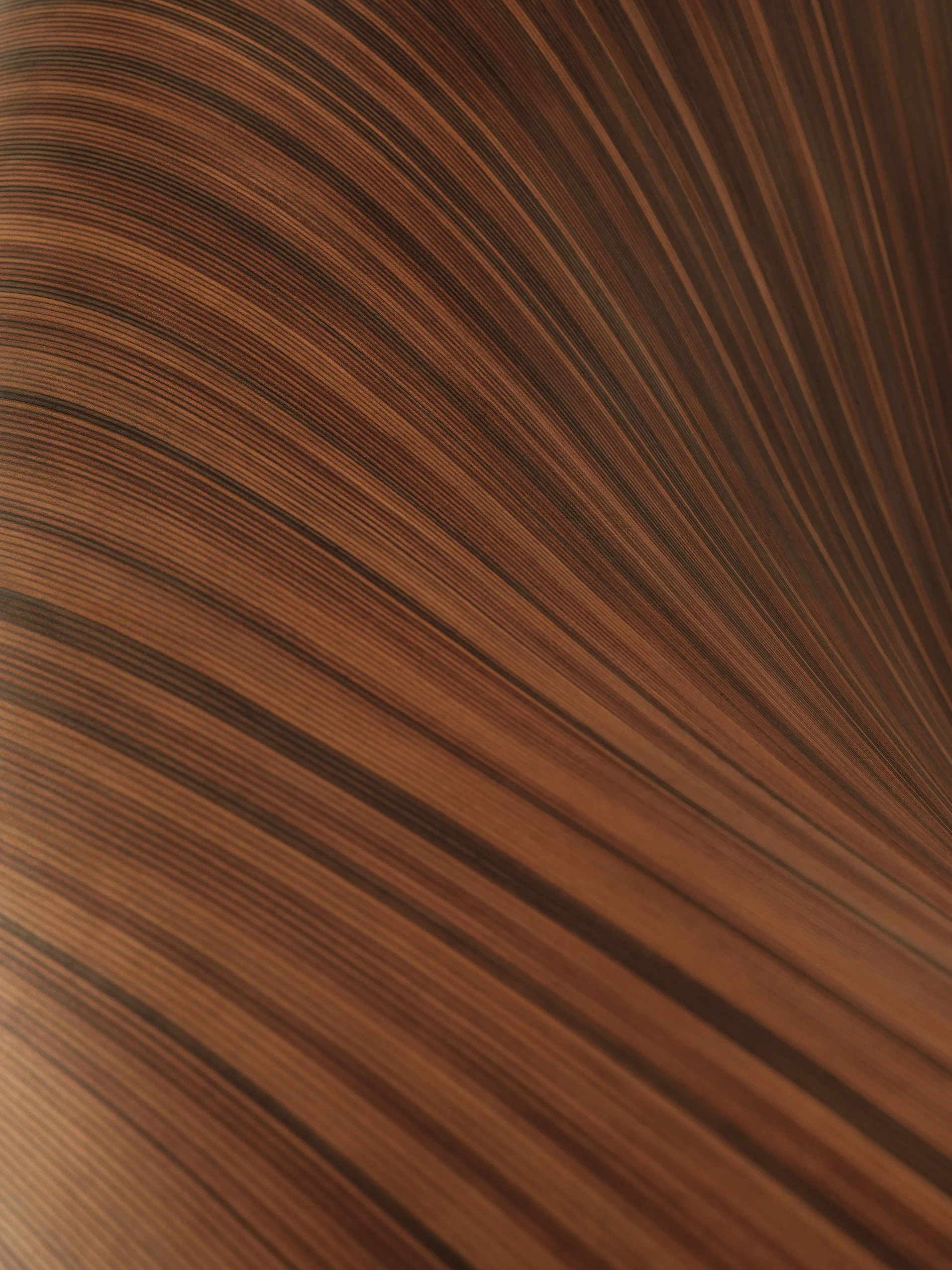

The Wave Console uses leather cording not as decoration but as the surface itself. Over 1,200 individual strips, salvaged from waste leather, cut to 2.8mm thickness were laid by hand over a bio-based flax composite structure shaped like breaking waves.

Instead of traditional spirals, the strips flow directionally, following the wave's contours like water finding its path. As each piece bonded to the three-dimensional surface, it responded, growing thicker here, tapering there. After application, each strip was spokeshaved smooth, blending seamlessly into the next. We left the fibrous cut edge exposed rather than the polished grain, the rough rather than the refined.

Why it Endures

In a world optimized for speed, leather cording is defiantly slow. You cannot program a machine to feel when tension is right or adjust for shifting leather grain. You cannot automate the judgment required or rush the patient accumulation of one cord after another.

Perhaps that is why it endures. Leather cording does not just cover a surface it transforms it. It adds warmth where metal would feel cold. It creates grip where wood might slip. It invites touch in ways smooth surfaces never quite manage.

When you run your hand across those 1,200 strips, you're feeling the hours embedded in them. The decisions made strip by strip. The patience of hands that knew this could not be rushed.

This is what we do at Silverlining: take techniques refined over centuries and reimagine them. Leather cording for sword grips becomes leather cording for sculptural furniture. The precision remains absolute. What emerges is furniture that carries a story in every strip.

The ancient art of leather cording, still speaking in a North Wales workshop, still proving that some things cannot and should not be rushed.

Subscribe to our newsletter

Sign-up to receive our newsletter and discover our stories, collections and latest innovations.