Unexpected Forms

For Studio SL, Silverlining's creative design studio, an unexpected form is not a stylistic choice. It is the result of asking a harder question than the brief requires, and refusing to stop until the answer is both structurally sound and visually complete. Two decades of work across bespoke commissions and limited editions have produced furniture that bends perception, revives techniques on the edge of extinction, and solves structural problems that have no precedent. Four pieces from Studio SL’s contemporary furniture design portfolio demonstrate what unexpected form means in practice.

infinity Table

The design thinking that shaped Studio SL's approach developed over years thanks to bespoke commissions from inspiring clients requesting solutions nobody had thought possible to achieve. The Infinity Table, from the Future Perfect collection, is one expression of that thinking.

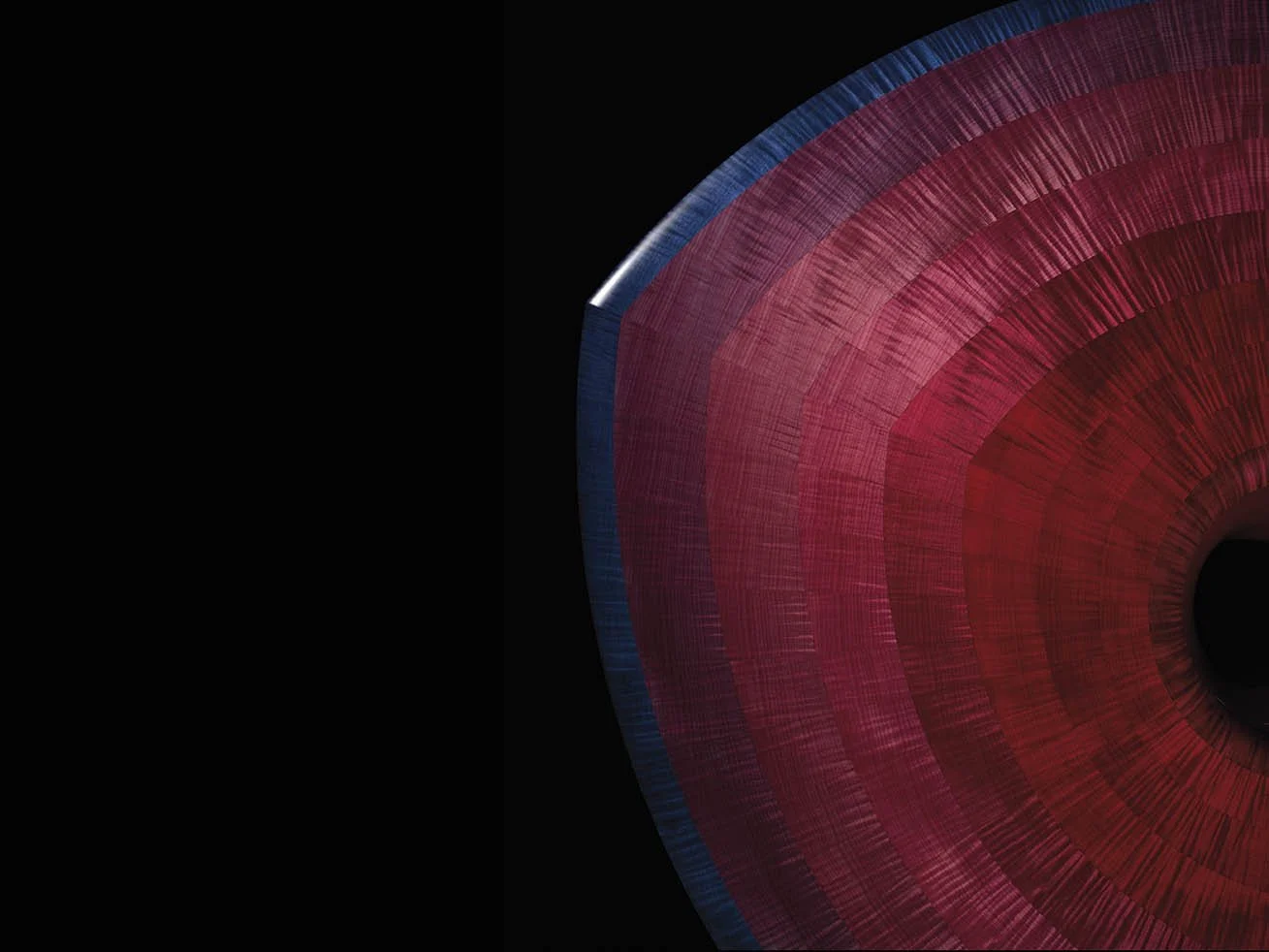

The table was designed around a void. At its centre, a trumpet-shaped opening draws the eye downward, creating the illusion of infinite depth. The void is the organising principle of the entire piece. Every element flows from it.

What makes the form unexpected is what happens next. Rather than ending at the base, the void exits the table and splits into three ribbon legs that peel back and flow directly into the underside of the tabletop, creating a single continuous form.

Creating the form demanded two distinct engineering challenges, each as exacting as the other. The first was structural: achieving the compound curves of the Reuleaux triangle shape with the precision required to make the ribbon legs and void read as a single uninterrupted form. This required engineering the entire piece from a single mould composite, the only method capable of creating an uninterrupted transition from void to leg to tabletop surface. The second challenge was material: coaxing curved sycamore veneer to follow every contour of that form without seam or break. Bending veneer across a compound curve of this complexity demands absolute accuracy at each stage in sequence. The continuity of the surface depends upon it.

The surface completes the effect. The outer surfaces, where hands make contact and light falls most directly, are finished in natural rippled sycamore veneer, its warmth rooting the piece in the familiar. Moving inward, the surface transitions to vivid red gloss lacquer, protected within the interior of the form and deepening the sense of infinite descent into the void. It is a shift that works on the senses quietly and completely, as though the table exists somewhere between the natural world and something altogether more extraordinary.

Urushi Breakfast Table

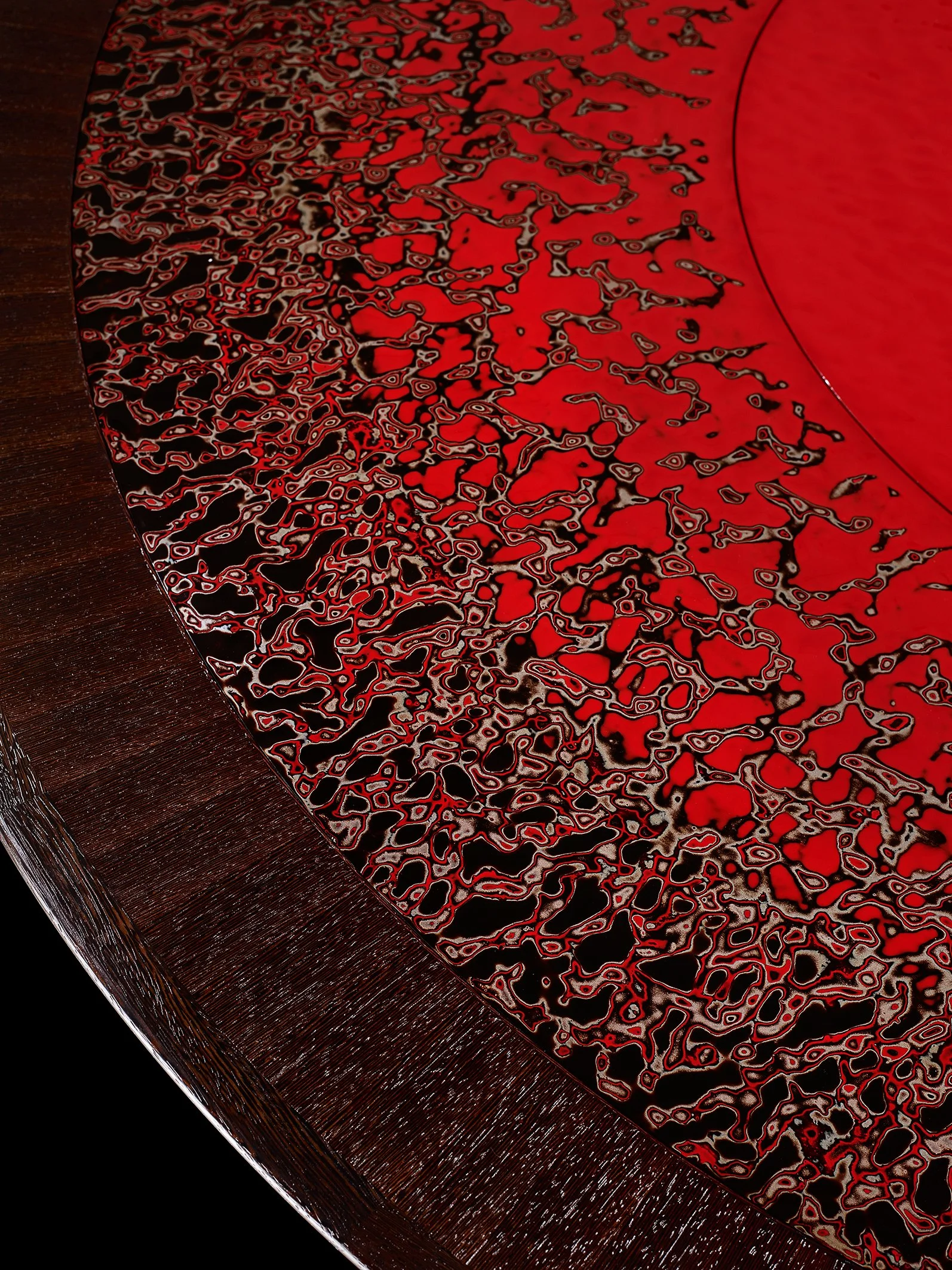

At first glance, the Urushi Breakfast Table is a study of the surface. The tabletop required twelve layers of urushi lacquer, each applied by hand. Urushi is a 12,000-year-old Japanese technique using sap gathered from the urushi tree. The process took six months. The result is a surface of extraordinary depth, its hues shifting between lava red, silver and charcoal black.

But the unexpected form is not the surface. It is the table’s base.

Inspired by the gyroscope, the base is constructed from interlinked circlets of wenge wood and mirror-polished nickel, flowing into one another in continuous sculptural forms. The interlocking circular forms provide no flat surfaces for mounting fixings, making assembly extraordinarily difficult. Wenge and nickel respond differently to temperature and humidity, their differing physical properties working against each other throughout construction. The solution was methodical. A framework was built around the intersecting rings, functioning like scaffolding, allowing each circlet to be fixed in place individually and finely adjusted before the next was secured. The base was assembled piece by piece, its final form the result of accumulated precision.

Cosmic Dining Table

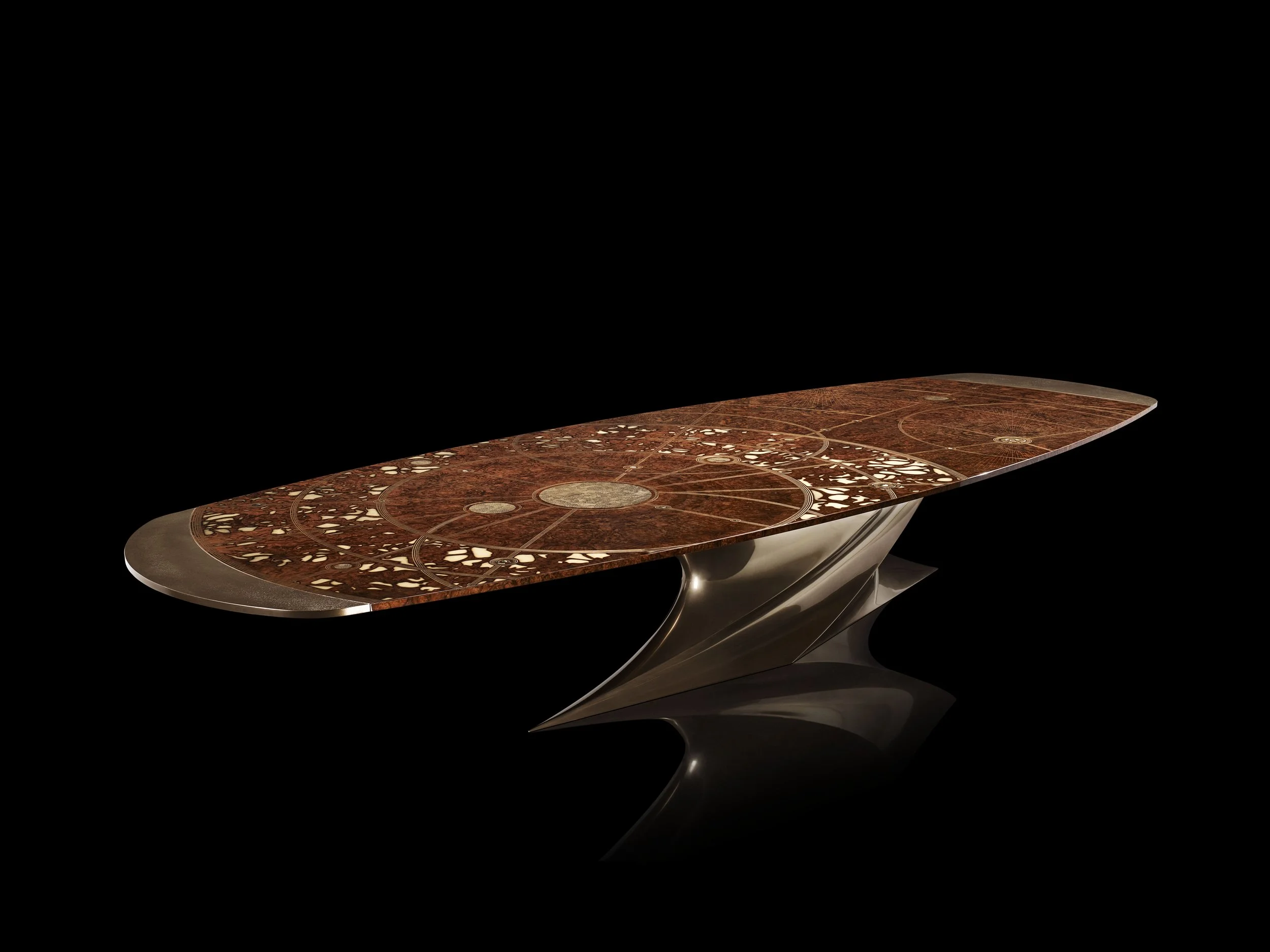

The brief for the Cosmic Dining Table, made for the superyacht Artefact, was one of the most demanding Studio SL had received: a dining table nearly five metres in length, supported by a single base, that felt monumental in presence yet weightless in form.

The challenge was immediate and significant. A table of that span, resting on a single point of support, generates enormous cantilever forces across its length. In conventional furniture construction, a table of this scale would require multiple legs or a substantial plinth to distribute that load. The brief allowed for neither.

The solution came from outside the world of furniture entirely. The underside of the tabletop was constructed from Kevlar, aluminium and carbon fibre, while the core borrowed the honeycomb structure used in aircraft wing engineering — the only method capable of achieving the rigidity required across five metres while keeping the form light enough to feel suspended rather than solid. The twisted base in polished gold metallised resin was then engineered to carry and distribute the structural load of that span through a single form, its geometry torqued and stretched to follow forces that are invisible to the eye but fundamental to the piece standing at all.

The tabletop’s surface design was then conceived in three distinct layers.

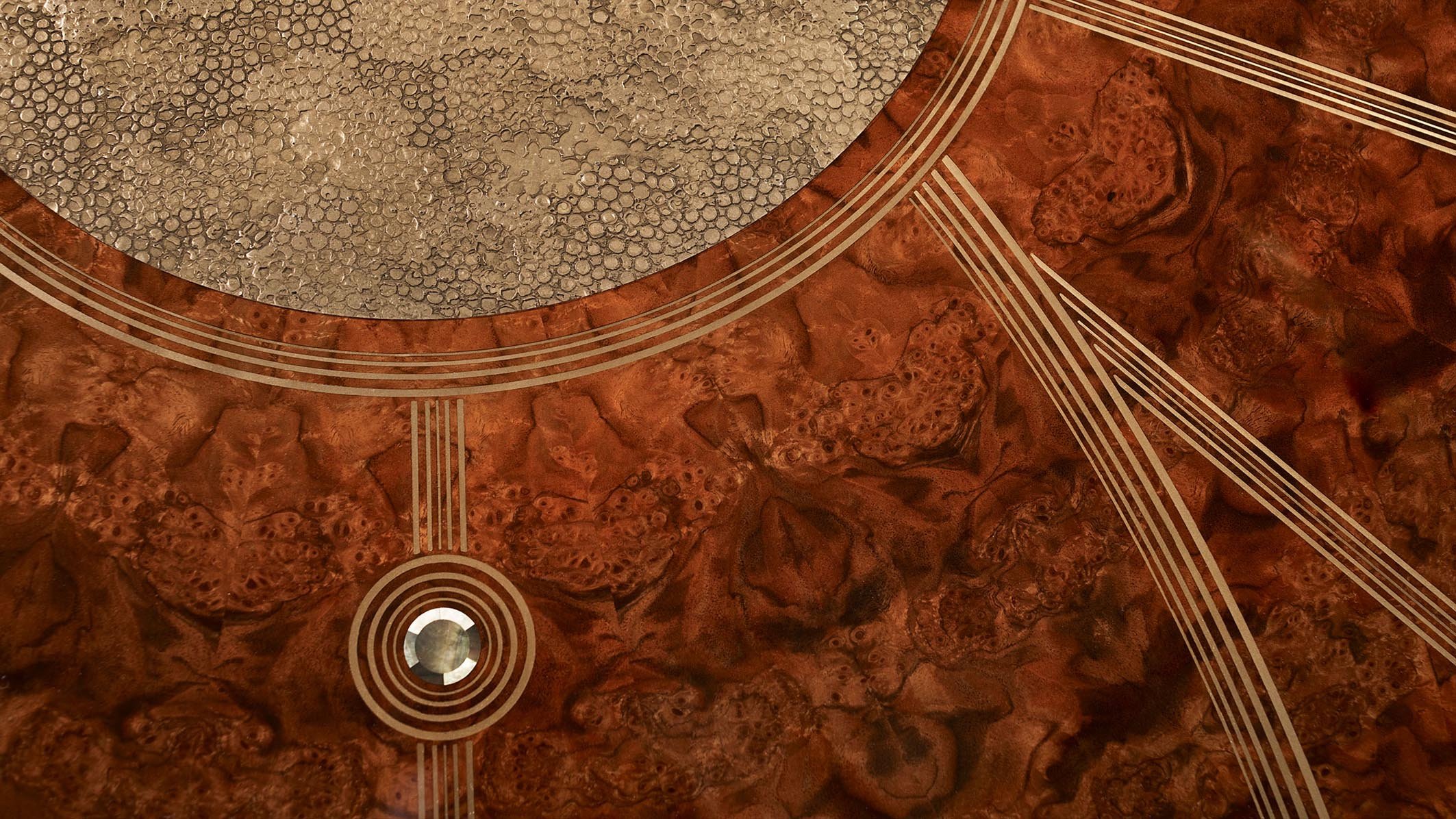

The foundation is American black burr walnut veneer, bookmatched radially from a central point, its pieces arranged outward like rays so that the grain mirrors itself symmetrically across the surface. The burr figuring was selected deliberately - its natural clusters, flares and nebulous formations akin to the cosmic chaos. The material becomes the atmospheric background upon which the rest of the composition unfolds.

The second layer introduces etched cosmic patterning in fine gold metallised lines, varying in width and density across the surface. The variation creates soft halos and fragmented orbital rings. As the eye moves across the table, new details emerge.

The final layer brings together three materials with contrasting reflective qualities. Gold leaf introduces warmth and luminosity. Metallised resin detailing absorbs and fractures light in a more tactile way. Mother-of-pearl inlays punctuate the surface as small stars and orbiting fragments.

Wave Console

The Wave Console began with a single question: could leather capture the movement and sensation of a breaking wave across an entirely curved, flowing form?

The challenge was structural before it was aesthetic. A wave form presents an immediate structural challenge. The crest, the highest and furthest point of the curve, extends beyond the base with nothing beneath it to carry the load. The further that point extends, the greater the force bearing down on it. At the scale of the Wave Console, that force is considerable.

The solution was a bio-based flax composite core, engineered to carry the cantilever's load at its furthest point while following the precise geometry of the wave form. Rigid enough to bear weight. Shaped exactly enough to disappear. The core exists entirely to make the leather possible.

Over 1,200 individual strips of vegetable-tanned coach hide were then hand-applied across the composite structure, each spokeshaved smooth as it followed the console's flowing curves. The cordings were sourced from waste leather in Havana, Papaya and Mocha tones. The fibrous cut edge was left deliberately exposed - a detail that turns a traditional leatherwork convention on its head. Where most leather craft conceals its construction, the Wave Console makes it visible.

The result appears effortless. The wave crests, holds, and flows back into the wall with no visible means of support. What the eye does not see is the months of structural engineering that made that possible.

Studio SL's work begins with questions that have no obvious answers, and that is precisely where the studio thrives. A void as the organising principle of an entire form. A base that cannot be fixed yet must hold. A five-metre surface that carries the presence of a monument and the lightness of air. Leather that captures the sensation of water in motion. These are the questions that define Studio SL's design thinking, and the pursuit of their answers is what drives every piece forward. The studio's second collectible design collection is currently in development, launching in autumn 2026.

Subscribe to our newsletter

Sign-up to receive our newsletter and discover our stories, collections and latest innovations.